Secrets You May Not Know: Manufacturing Of Corrugated Boxes

The manufacturing of corrugated boxes is a fascinating process that often goes unnoticed. These versatile boxes are used for packaging various products and play a crucial role in supply chains worldwide.

In this blog, we will uncover some secrets about the manufacturing of corrugated boxes, shedding light on the intricate processes involved and their importance in the packaging industry.

Understanding Corrugated Boxes:

What are Corrugated Boxes?

Fluted paper and linerboard are the two main components of corrugated boxes. They feature a wavy, rigid structure that provides strength and durability while maintaining lightness. These boxes are popular for packaging because they are versatile, cost-effective, and easy to use.

The Importance of Corrugated Boxes

Corrugated boxes serve as the backbone of the packaging industry. Their ability to protect and transport a wide range of products makes them invaluable in various sectors, including e-commerce, retail, and logistics.

The following are key points to keep in mind when considering corrugated boxes:

- Protection of Goods:

Corrugated boxes offer exceptional protection for the products they hold. The rigid structure and stacking strength of these boxes prevent damage caused by external pressures during transportation and storage.

This is especially crucial when shipping fragile or delicate items, as the cushioning properties of corrugated boxes help absorb shocks and vibrations, reducing the risk of breakage.

- Versatility:

Corrugated boxes are highly versatile and can accommodate a wide range of products. They come in various shapes and sizes, allowing for customization based on specific packaging requirements.

Corrugated boxes are useful for protecting all kinds of items, from small electronics to large appliances.

- Cost-effectiveness:

One of the key advantages of corrugated boxes is their cost-effectiveness. They are less expensive than many other packaging materials, making them a good choice for businesses.

Moreover, their lightweight nature helps minimize shipping costs, as they contribute less to the overall weight of the packaged goods. The affordability and efficiency of corrugated boxes make them a practical solution for businesses of all sizes.

The Manufacturing Of Corrugated Boxes Process:

Corrugated boxes are made from a combination of paper and cardboard. The process of manufacturing corrugated boxes involves many steps:

A. Raw Materials:

The manufacturing process begins with the selection of high-quality raw materials. The linerboard, made from long fibers, provides the outer surface of the box, while the fluted paper forms the middle layer, adding strength and resilience to the structure.

B. Corrugating:

Corrugating is the process of creating the characteristic waves in the fluted paper. The paper passes through corrugating rolls, which apply heat and pressure to form the desired pattern. The type of flute used determines the box’s strength and flexibility.

C. Adhesive Application:

Once the fluted paper is corrugated, it is combined with the linerboard using a starch-based adhesive. The adhesive is applied precisely to ensure strong bonding between the layers, forming a rigid structure that can withstand external forces.

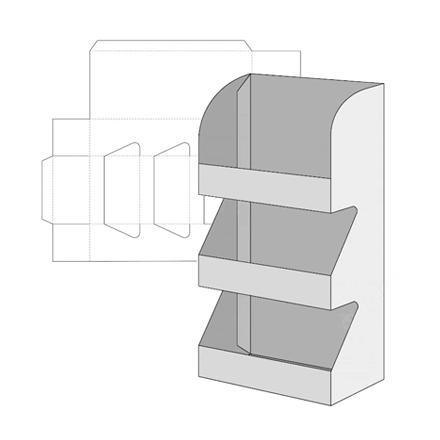

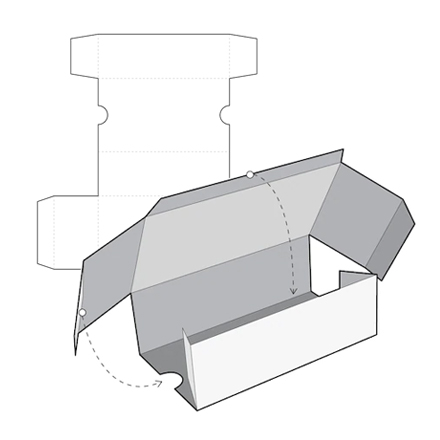

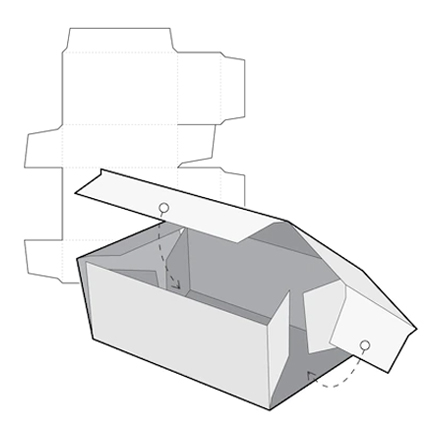

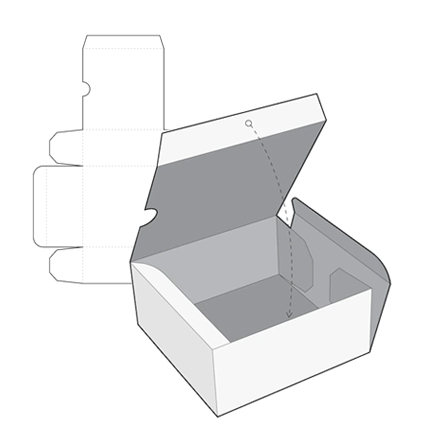

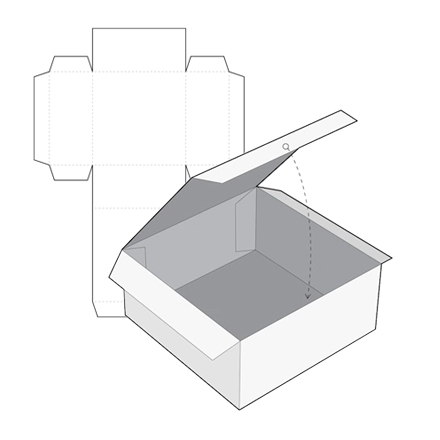

D. Cutting and Creasing:

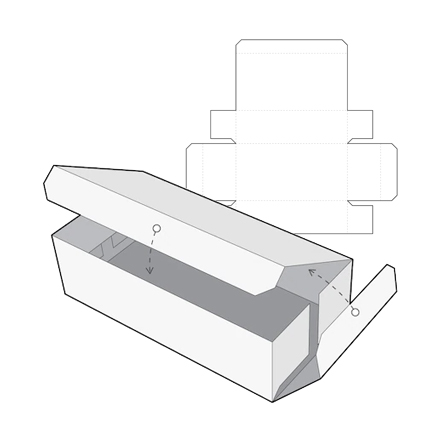

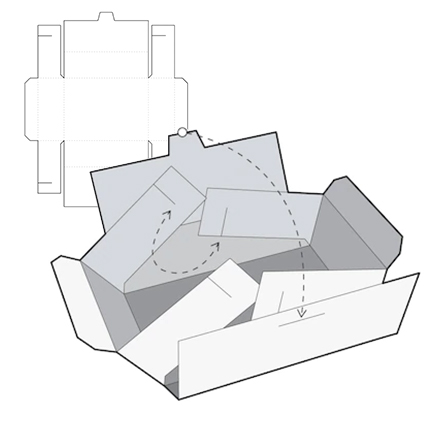

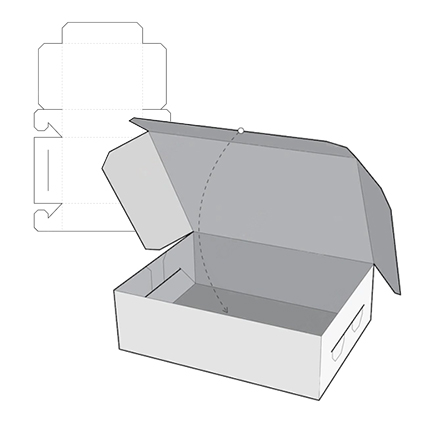

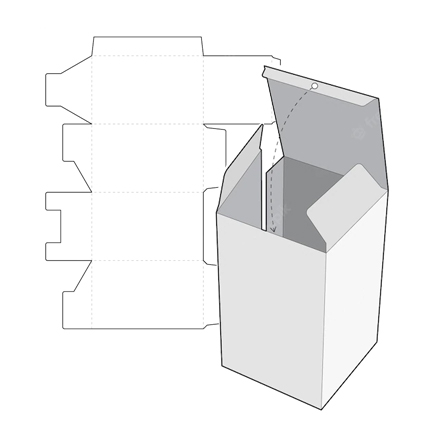

After the adhesive has dried, the corrugated board goes through cutting and creasing machines. These machines cut the board into desired dimensions and create creases that allow for easy folding and assembly.

E. Printing and Finishing:

Printing on corrugated boxes not only adds branding elements but also enhances their visual appeal. The printing process begins with the creation of a design. The type of box being produced determines the printing method used, such as flexography for short-run boxes and lithography for high-volume runs. Additionally, finishing processes like varnishing or laminating can be applied to enhance durability and appearance.

Innovations In Corrugated Box Manufacturing:

Companies that manufacture corrugated boxes have made many innovations to improve efficiency.

- Sustainable Manufacturing Practices

With increasing environmental concerns, manufacturers are adopting sustainable practices in corrugated box manufacturing. This includes using recycled and recyclable materials, reducing energy consumption, and implementing waste management systems. These efforts help minimize the industry’s carbon footprint and promote a circular economy.

For example, the materials used in JERL’s manufacturing of corrugated boxes are fully recyclable. This is a good choice for companies or brands that focus on environmental protection.

- Customization and Design Advancements

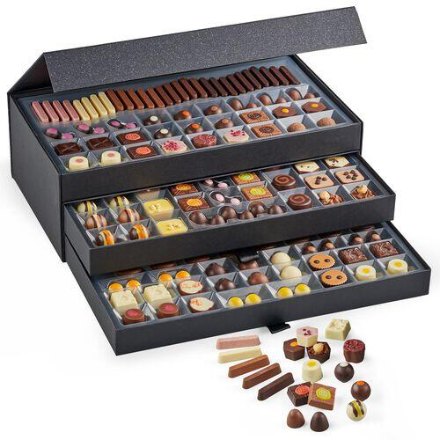

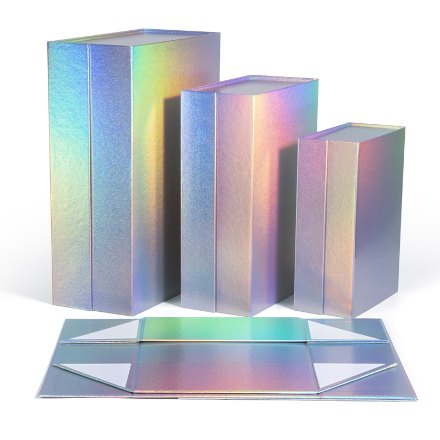

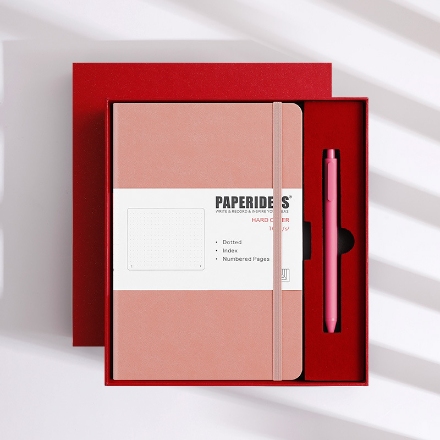

Advancements in technology have enabled manufacturers to offer customizable corrugated boxes tailored to specific product requirements. From unique shapes and sizes to intricate designs and printing, manufacturers can now cater to individual branding needs, enhancing product visibility and customer experience.

- Various Choices:

In addition to simple corrugated boxes, JERL also provides many packaging solutions suitable for high-end electronic products, expensive skin care products, and so on. JERL has a wide range of products for packaging electronic products, including boxes for watches, smartphones, and earphones.

In addition, you can customize their boxes to fit the size and shape of your electronics for extra security.

Quality Assurance And Compliance:

Take JERL’s manufacturing of corrugated boxes as an example. They carefully produce each product through a rigorous process, which greatly improves the quality.

a. Stringent Quality Control Measures

Manufacturers follow strict quality control measures to ensure that corrugated boxes meet industry standards. These measures involve testing for compression strength, bursting strength, and stacking capability.

Quality control checks at each stage of the manufacturing of corrugated boxes process help maintain consistency and reliability.

b. Compliance with Regulations

Corrugated box manufacturers adhere to various regulations and certifications, such as the International Organization for Standardization (ISO) standards and Forest Stewardship Council (FSC) certification.

These ensure that the manufacturing of corrugated boxes process meets specific criteria for quality, sustainability, and responsible sourcing.

Final words:

The manufacturing of corrugated boxes involves intricate processes and continuous innovation. Understanding the secrets behind their production highlights their significance in the packaging industry.

From raw material selection to printing and finishing, each step contributes to creating durable, sustainable, and customizable packaging solutions.

By unveiling these secrets, we gain a deeper appreciation for the manufacturing of corrugated boxes and their vital role in protecting and transporting goods worldwide.

JERL has been working hard on the road of custom packaging. Next time when you feel the need to impress someone with your brand, think of JERL Packaging!