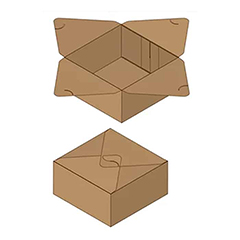

Box Guide

Corrugated packaging box is a common packaging material, which is widely used in various industries and fields. It protects items from damage and contamination and provides a good display platform. Corrugated packaging boxes come in a variety of materials, so there are many factors to consider when choosing the right corrugated packaging box, such as product type, weight, size, and shipping method. This article will introduce several common corrugated packaging box materials, as well as their advantages and disadvantages.

Single-layer corrugated box

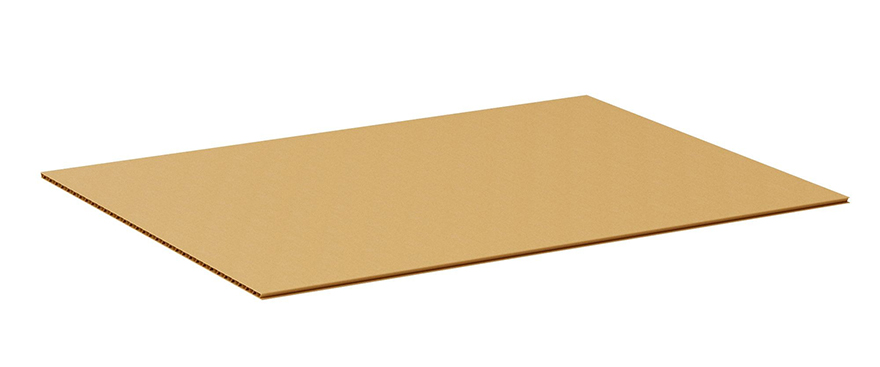

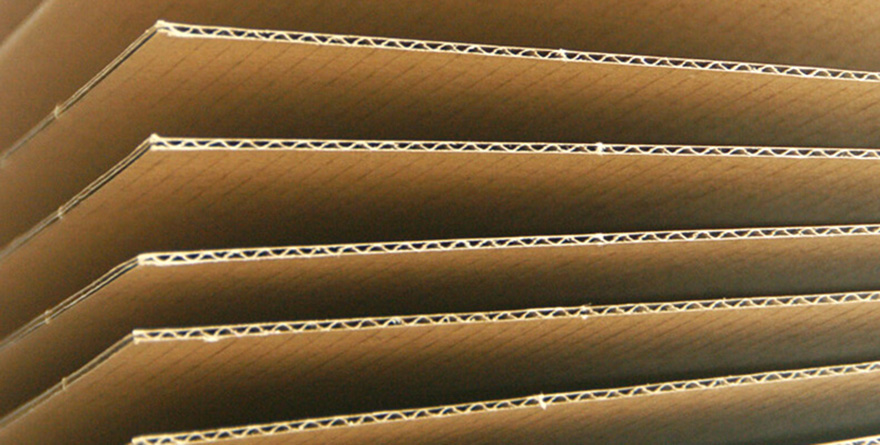

Single-ply corrugated packaging boxes are the simplest and most basic packaging boxes and are usually used for lightweight items. It is made of one layer of corrugated cardboard, which is low cost and sustainable. However, single-layer corrugated packaging boxes have relatively low strength and are not suitable for transporting and protecting heavy or fragile items.

Double-layer corrugated box

Double-wall corrugated boxes are stronger and more stable than single-wall corrugated boxes and are often used to protect heavier or more valuable items. It is made of two layers of corrugated cardboard with a layer of film in between, which can increase the strength and stability of the box. Double-wall corrugated boxes cost more than single-wall corrugated boxes, but are relatively less expensive.

Three-layer corrugated paper packaging box

Three-ply corrugated packaging boxes are one of the most common types of corrugated packaging boxes and are typically used to protect medium weight and sized items. It is made of triple-layer corrugated cardboard for greater strength and durability. Three-ply corrugated boxes cost slightly more than double-ply corrugated boxes, but are still relatively inexpensive.

Four-layer corrugated paper packaging box

Four-layer corrugated packaging boxes are relatively more stable, including two layers of outer liner, one layer of inner liner and a middle layer of grooves, usually used to protect heavier or fragile items. They offer better protection, can withstand a lot of crushing and impact, and are suitable for packing clothes, books and small appliances. However, since they use more material, they cost more.

Five-layer corrugated packaging box

A five-layer corrugated box is a box made of five layers of material, including two layers of outer lining paper, two layers of inner lining paper, and a middle layer of grooves. The grooved layer provides cushioning and strength to the box, while the backing acts as a protective barrier against moisture and other external elements. They are typically used for transport and storage of products that require a moderate level of protection, such as electronics, toys and food.

In addition, in order to protect the environment, it is also a good choice to choose sustainable corrugated packaging boxes.

Biodegradable corrugated packaging boxes:

These boxes are typically made from natural materials such as pulp and starch. They can naturally decompose in a short period, reducing their impact on the environment. This type of packaging box is a good choice when long-term storage is not needed.

Recycled corrugated packaging boxes:

These boxes are made from recycled paperboard materials, reducing waste and resource waste. Recycled paperboard materials can come from industrial waste or consumer-recycled paper. This type of packaging box can save energy and reduce pollution during the manufacturing process.

Paper cushioning:

Paper cushioning is an innovative packaging material that can be used to protect fragile items. They are made from special pulp and natural materials such as starch and can decompose in water, reducing their impact on the environment. This packaging material is not only biodegradable but also effectively protects the product.

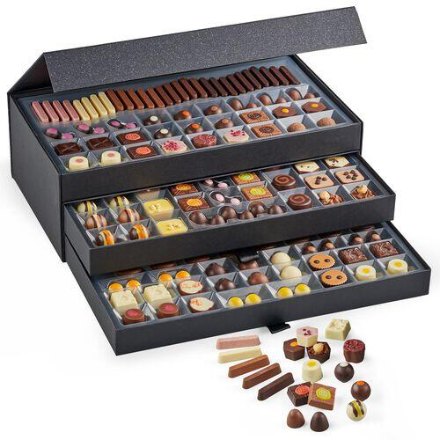

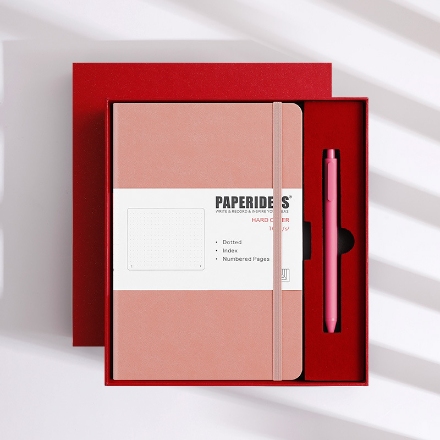

Reusable corrugated packaging boxes:

These boxes are typically made from sturdy paperboard and can maintain their shape and performance through multiple uses. This type of packaging box can reduce waste generation and lower costs.

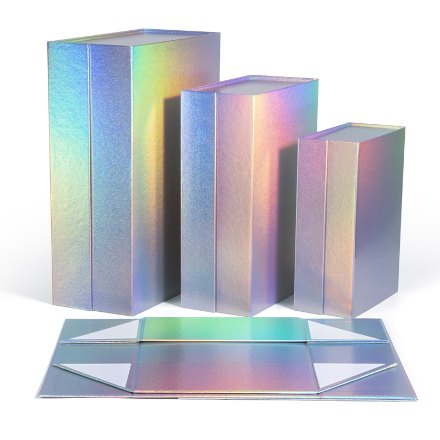

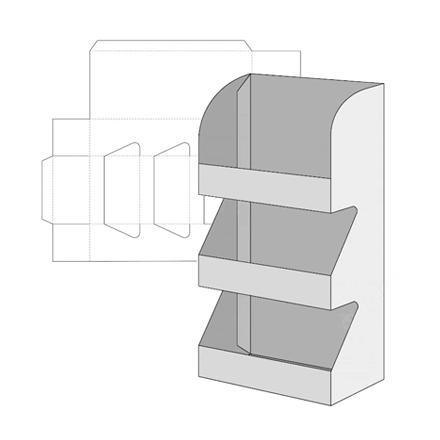

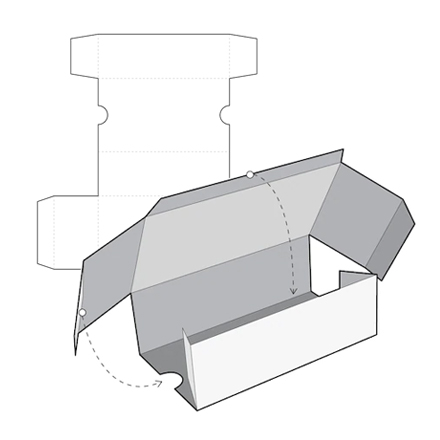

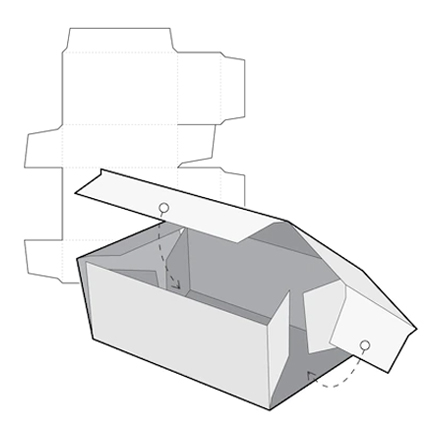

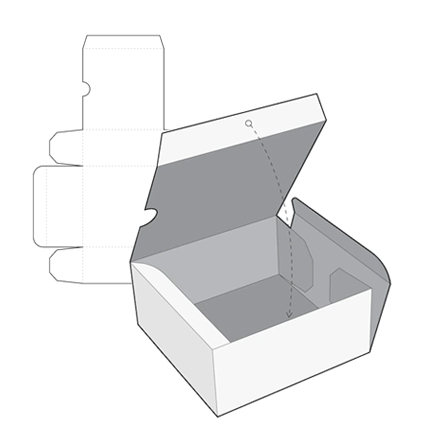

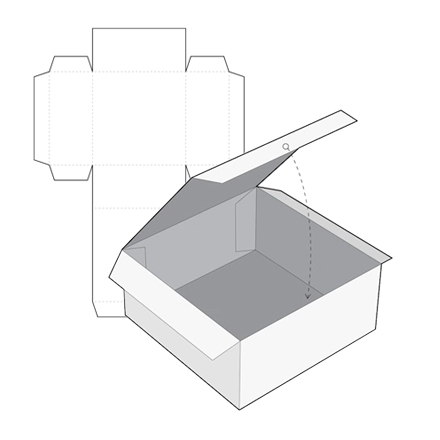

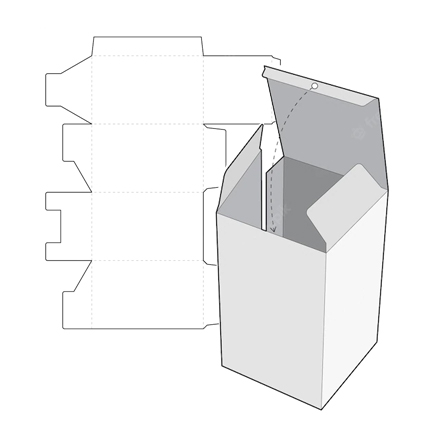

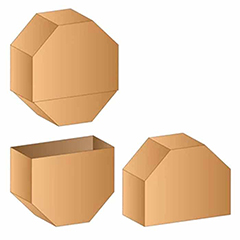

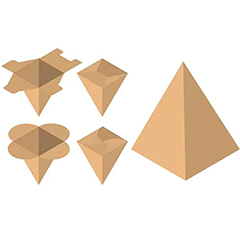

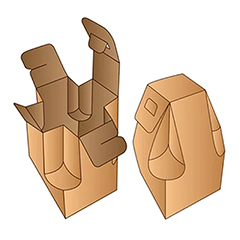

If you need to customize corrugated packaging boxes of special sizes or shapes, you need to contact the packaging supplier and provide detailed specifications. JERL has done a good job in this area. We have more than ten years of experience. Compared with the price, we may not be as good as your local service provider, but we can do more, more complete and more difficult styles, and they support any material. And we can complete orders more quickly.

Professional corrugated packaging supplier