In What Industries Are Die Cut Boxes Wholesale Most Widely Used?

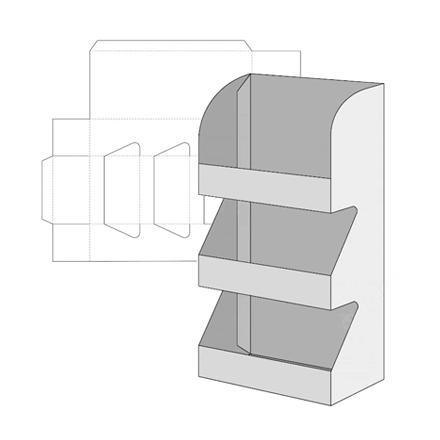

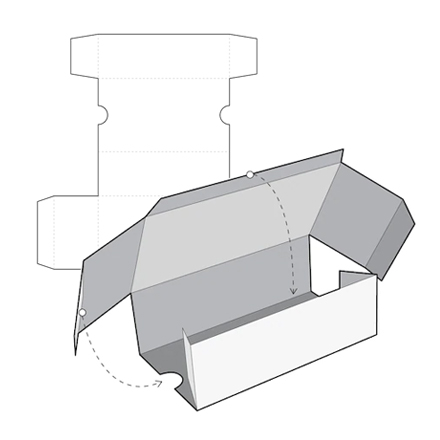

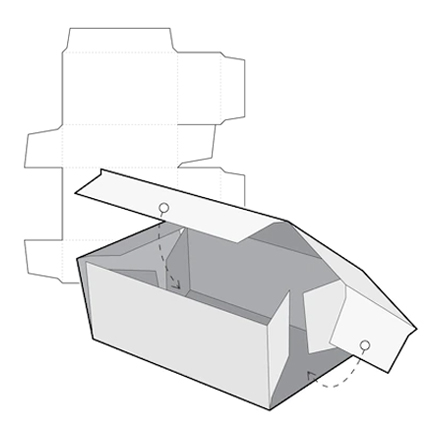

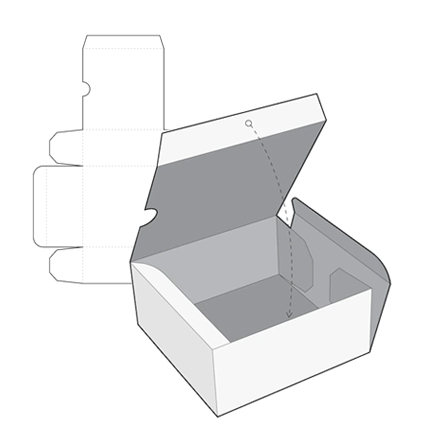

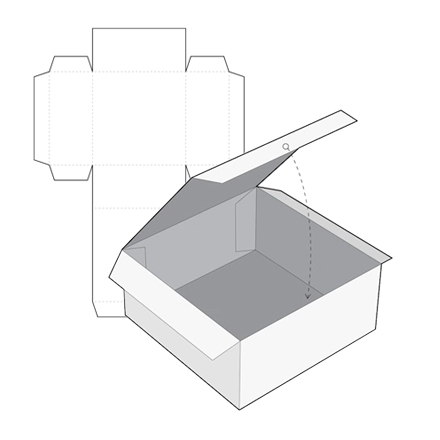

Die cut boxes have revolutionized the packaging industry with their precision-cut designs and versatility. Unlike regular boxes that are pre-made and folded into shape, die cut boxes are crafted using a specialized die cutting machine. This process allows for intricate shapes, sizes, and designs to be easily achieved, making them ideal for a wide range of products.

Introduction to Die Cut Boxes wholesale

1.1 Definition of Die Cut Boxes

Die cut boxes are packaging containers that are custom-designed and cut using a die cutting machine. These boxes are tailored to fit specific products, providing a snug and secure fit, which helps prevent damage during shipping and handling.

1.2 Advantages of Die Cut Boxes

Die cut boxes offer several advantages over traditional packaging solutions. Firstly, their customizability allows businesses to create packaging that perfectly showcases their products, enhancing brand visibility and appeal. Additionally, die cut boxes are often made from sturdy materials, providing superior protection for fragile or valuable items. Their precise fit also reduces the need for excess packing materials, making them more environmentally friendly.

1.3 Introduction to Wholesale Purchasing

Wholesale purchasing involves buying goods in large quantities at discounted prices. When it comes to die cut boxes, wholesale purchasing offers numerous benefits for businesses looking to optimize their packaging solutions.

Benefits of Wholesale Die Cut Boxes

2.1 Cost-Effectiveness

Purchasing die cut boxes wholesale from manufacturers like JERL can result in significant cost savings for businesses. Buying in bulk allows for economies of scale, leading to lower per-unit costs compared to buying individual boxes. This cost-effectiveness is particularly advantageous for businesses with high packaging needs or those operating on tight budgets.

2.2 Bulk Purchasing Savings

Wholesale die cut box manufacturers like JERL often offer discounts and incentives for bulk purchases. By ordering large quantities upfront, businesses can take advantage of these savings, reducing their overall packaging expenses. Furthermore, bulk purchasing helps streamline the procurement process, saving time and resources.

2.3 Flexibility and Customization

One of the key advantages of ordering die cut boxes wholesale is the flexibility and customization options available. Manufacturers like JERL can accommodate a wide range of specifications, including size, shape, material, and printing design. This customization allows businesses to create packaging that aligns with their branding and product requirements, enhancing the overall presentation and appeal.

Applications of Die Cut Boxes in Various Industries

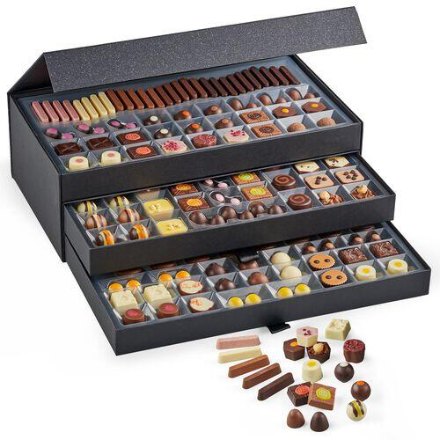

3.1 Food and Beverage Industry

Die cut boxes are widely used in the food and beverage industry for packaging products such as chocolates, confectionery, and beverages. Their customizable designs allow for attractive packaging that highlights the freshness and quality of the contents. Case studies have shown that die cut boxes can improve shelf appeal and drive sales in this competitive market.

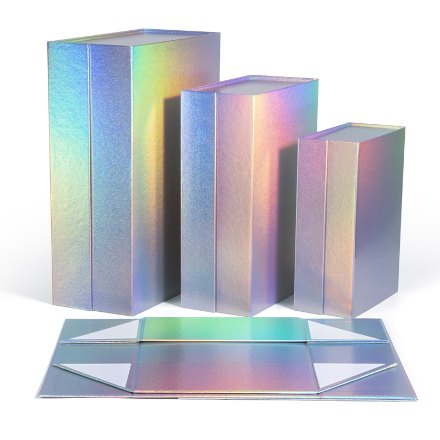

3.2 Cosmetics Industry

In the cosmetics industry, presentation is key, and die cut boxes offer a perfect solution for showcasing beauty products. Whether it’s skincare creams, makeup palettes, or perfume bottles, die cut boxes can be tailored to fit various shapes and sizes, providing a luxurious and elegant packaging solution. Examples from leading cosmetic brands demonstrate how die cut boxes can elevate the perceived value of products and enhance brand recognition.

3.3 Electronics Industry

The electronics industry often requires packaging solutions that provide both protection and aesthetics. Die cut boxes excel in this regard, offering sturdy construction and customizable designs that meet the specific requirements of electronic devices. Case studies have highlighted the effectiveness of die cut boxes in reducing shipping damage and improving the unboxing experience for consumers.

Customization Options for Die Cut Boxes

Die cut boxes offer a plethora of customization options, allowing businesses to tailor their packaging to suit their specific needs and branding requirements. From size and shape to design and printing, the possibilities are virtually endless.

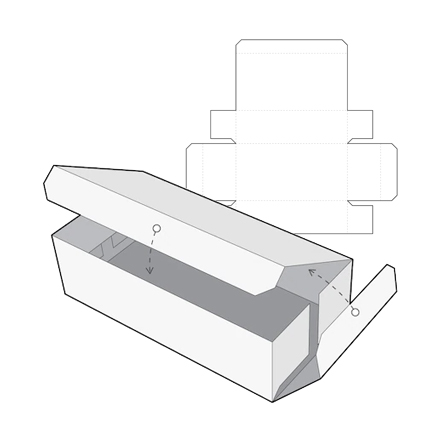

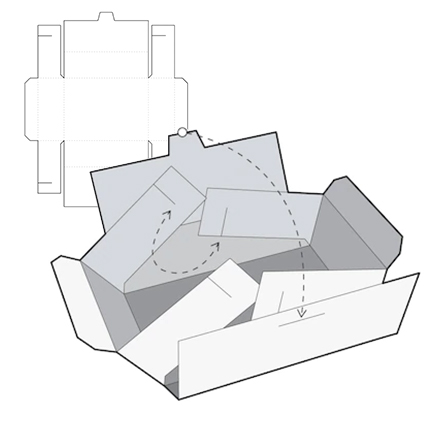

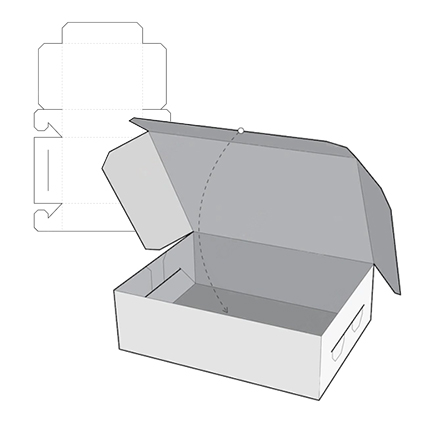

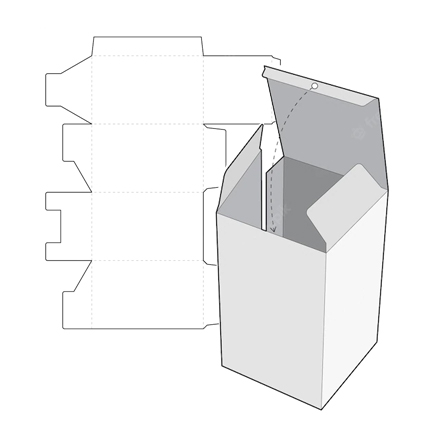

4.1 Size and Shape

One of the primary advantages of die cut boxes is their ability to be customized in terms of size and shape. Whether you need a small, compact box for delicate items or a larger, more spacious one for bulkier products, die cut boxes can be tailored to fit virtually any dimensions.

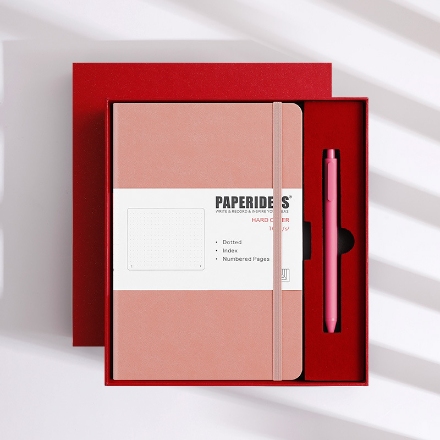

4.2 Design and Printing

Die cut boxes can also be customized in terms of design and printing. Businesses can choose from a variety of designs, including simple and minimalist or bold and eye-catching. Additionally, printing options such as logos, product information, and branding elements can be seamlessly incorporated into the box design, helping to enhance brand recognition and product presentation.

4.3 Enhancing Branding and Product Presentation

Customization plays a crucial role in enhancing branding and product presentation. By incorporating brand colors, logos, and design elements into the packaging, businesses can create a cohesive and memorable brand experience for their customers. Additionally, customized die cut boxes help products stand out on store shelves, attracting the attention of potential buyers and driving sales.

Tips for Creating Custom Die Cut Boxes

When creating custom die cut boxes, businesses should consider several factors to ensure the end result meets their expectations. Firstly, it’s essential to clearly communicate your requirements to the manufacturer, including size, shape, design, and printing specifications. Additionally, requesting samples or mock-ups before placing a bulk order can help ensure that the final product meets your expectations. Finally, working with a reputable manufacturer like JERL can provide valuable expertise and guidance throughout the customization process.

5.1 Choosing the Right Die Cut Box Supplier

Selecting the right die cut box supplier is crucial for ensuring the quality, reliability, and affordability of your packaging solutions. Here are some factors to consider when making your decision:

5.2 Quality and Reliability

Choose a supplier that prioritizes quality and reliability in their products. Look for manufacturers that use high-quality materials and advanced manufacturing processes to ensure the durability and integrity of their die cut boxes. Additionally, consider the supplier’s track record and reputation within the industry to gauge their reliability.

5.3 Pricing and Cost-effectiveness

While pricing is an important consideration, it’s essential to strike a balance between cost-effectiveness and quality. Avoid suppliers that offer excessively low prices, as this may indicate inferior quality or subpar materials. Instead, look for suppliers like JERL that offer competitive pricing without compromising on quality.

5.4 Customer Service and Support

A reliable supplier should provide excellent customer service and support throughout the ordering process. Look for suppliers that are responsive to inquiries, provide timely updates on order status, and offer assistance with any issues or concerns that may arise. Establishing a good working relationship with your supplier is essential for long-term success.

5.5 Checklist for Supplier Selection

To help streamline the supplier selection process, consider creating a checklist of criteria to evaluate potential suppliers. This checklist may include factors such as quality, reliability, pricing, customer service, and any specific requirements or preferences you have for your packaging solutions.

5.6 Negotiating Contracts and Establishing Partnerships

When negotiating contracts with your chosen supplier, be clear and transparent about your expectations, including pricing, delivery schedules, and quality standards. Additionally, consider establishing long-term partnerships with your supplier to foster collaboration and mutual success. Regular communication and feedback can help strengthen your relationship with your supplier and ensure continued satisfaction with your packaging solutions.

Tips for Maximizing Efficiency with Die Cut Boxes

Efficiency is key when it comes to utilizing die cut boxes in your packaging processes. Here are some tips and best practices to help you maximize efficiency:

6.1 Optimizing Inventory Management and Storage

Maintaining an organized inventory management system is essential for ensuring that you have an adequate supply of die cut boxes on hand when needed. Implementing barcode scanning or RFID technology can help streamline inventory tracking and replenishment processes. Additionally, optimizing storage space by utilizing shelving, racks, or stackable containers can help minimize clutter and improve efficiency in your warehouse or storage facility.

6.2 Streamlining the Ordering and Fulfillment Process

Streamlining the ordering and fulfillment process can help minimize downtime and ensure the timely delivery of your packaging solutions. Consider implementing an automated ordering system or using electronic purchase orders to streamline the procurement process. Additionally, establishing clear communication channels with your supplier and providing accurate order forecasts can help prevent delays and ensure smooth order fulfillment.

6.3 Continuous Improvement and Innovation

Continuous improvement and innovation are essential for staying competitive in today’s fast-paced business environment. Regularly review your packaging processes and look for opportunities to streamline operations and reduce costs. Additionally, stay informed about new developments and innovations in die cut box technology to ensure that you are leveraging the latest advancements to optimize efficiency and enhance product quality.

Conclusion

Die cut boxes wholesale offer a cost-effective and versatile packaging solution for businesses across various industries. With their customizable designs and bulk purchasing benefits, these boxes provide a perfect combination of functionality and aesthetics. Whether it’s for food, cosmetics, electronics, or any other product category, die cut boxes from manufacturers like JERL are sure to enhance brand visibility and drive sales.

JERL has been working hard on the road of custom packaging. Next time when you feel the need to impress someone with your brand, think of JERL Packaging!