What kind of printing is most suitable for your product?

Foreword

- Do you know the packaging and printing process?

- Do you know what printing method your product needs?

- What can printing bring to your products?

I think this is a question that every brand that wants to match its products with good packaging will consider. We clearly know the importance of packaging, and we also want to give the product good packaging. We want the packaging to highlight the tonality of our brand and tell the brand story to the outside world, but we still don’t know how to use printing to achieve it.

Printing process and its characteristics

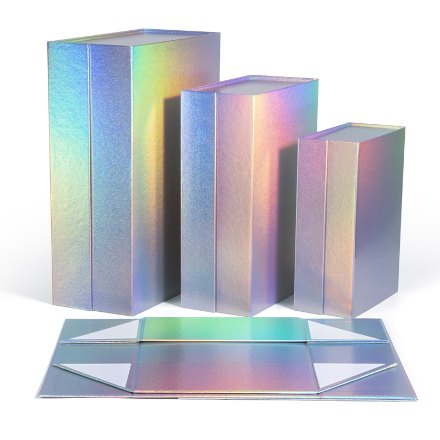

Spot UV printing process. Many people think that this is one of printing, but it is not. Spot UV is actually more of a coating method, which belongs to the post-printing process. This coating creates a tactile effect that can be felt by touch, adding visual and tactile interest to a drab box. We can apply layers directly to the print by using a separate printing pass with a dedicated UV coating unit, or using a digital UV printer. Its characteristics are as follows:

- Extreme shine: Spot UV can add luster, you might as well use Spot UV after printing your LOGO to make your LOGO shine exceptionally and look elegant!

- Environmentally friendly and harmless: As the name suggests, the coating is to coat a film on the surface of the box, which can provide protection for the box and enhance the durability of the box. The same is true for Spot UV. It can protect the color under the coating, prevent the box from being damp and damaged, and it is not highly volatile so it will not cause adverse effects on the environment. It is an environmentally friendly technology that can be widely used in market production.

- Anti-fouling and bright: The coating is essentially a thin film, which not only can effectively protect the bottom printing from being scratched, but also can be easily wiped off if the coating itself is dirty, so that the product packaging is always clean.

- Abnormal clarity: Spot UV has ultra-high-definition visual effects, which can make consumers feel comfortable and improve their experience during use.

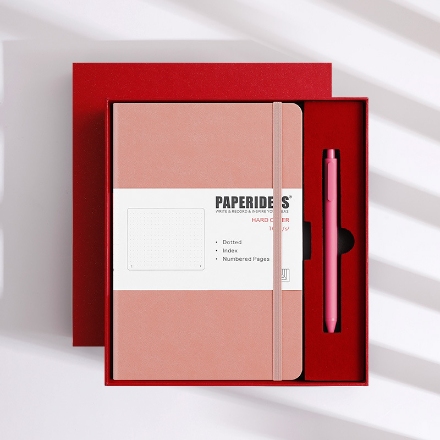

Embossing is used to describe raised designs or patterns on a surface, usually created by stamping or pressing materials such as paper, metal or leather. The embossing process involves creating a three-dimensional image or text by pressing it into the material from the back, making it evident on the front. Its characteristics are as follows:

- Raised Design or Pattern: The most distinctive feature of embossing is the raised design or pattern formed on the surface of the material.

- Tactile Elements: Raised designs or patterns provide a tactile element to a material, making it more visually appealing and unique.

- Three-dimensional effect: Embossing creates a three-dimensional effect that can add depth and texture to a design.

- Customizability: Embossing can be customized to suit personal preferences and design requirements. This can include choosing the size and shape of the relief design, as well as the type of material used.

- Enhances Brand: Embossing can enhance a product’s brand by creating a unique and memorable design that stands out from the competition.

Hot stamping is used to create a metallic finish on a variety of surfaces. It involves applying bronze-colored powder or paint to the surface to create the appearance of a metallic finish. Hot stamping can come in a variety of colors, including gold, silver, copper, and bronze. It can be used to create a variety of finishes including glossy, matte or textured. Hot stamping can add a touch of elegance and sophistication to any project, making it a popular choice for many applications. Its characteristics are as follows:

- Enhances aesthetics: Hot stamping can add a luxurious and sophisticated finish to a product or object, enhancing its overall aesthetic.

- Increased durability: Hot stamping can provide a layer of protection to the surface, making it more durable and resistant to wear and tear.

- Increase Perceived Value: The use of bronzing can increase the perceived value of a product or item, making it more attractive to customers and potentially increasing sales.

- Versatility: Hot stamping can be used on a variety of materials and surfaces, making it a versatile decorating technique.

- Customizability: Bronzing can be customized according to personal preferences and design requirements, allowing for a high degree of creativity and personalization.

CMYK color model. In color printing, the printer uses combinations of four colors (cyan, magenta, yellow, and black) to create a wide range of colors. This is often referred to as the CMYK color model. By varying the amount of each color used, a printer can produce an almost unlimited number of different colors. Its points are as follows:

- Versatility: Color printing can be used for a wide range of applications, including everything from basic documents to high-quality photos and marketing materials.

- Accuracy: Modern color printing techniques are capable of producing highly accurate color reproduction, ensuring that the colors in the printed material closely match the original image.

- Flexibility: With digital printing technology, a small number of copies of a document or image can be printed, making color printing ideal for small businesses or individuals who only need a few copies of a specific document or image.

- Cost-effective: While color printing may be more expensive than black-and-white printing, advances in technology have made it more affordable than ever, making it a cost-effective option for many businesses and individuals.

- Creativity: Color printing allows for a higher level of creativity in printed materials as it allows the use of a wide range of colors and color combinations, allowing the creation of striking and visually appealing designs.

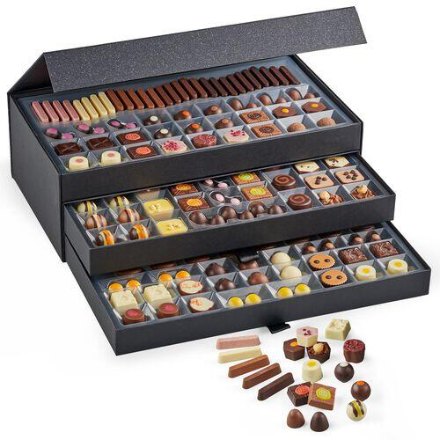

Flocking is the process of applying small fibers called flocking to a surface to create a textured or decorative effect. Flocking is usually made of nylon, rayon or other synthetic fibers and is applied to the surface using an adhesive. Its characteristics are as follows:

- Enhanced Appearance: Flocking can give packaging a luxurious, premium look and feel. The soft, velvety texture of flocked packaging can make a product more attractive to consumers and increase the perceived value of the product.

- Protection: Flocking can provide an extra layer of protection to the product by cushioning and preventing damage from impacts or scratches. This is especially important for fragile or delicate products.

- Anti-slip properties: Flocked packaging can have anti-slip properties, making it easier to handle and preventing the product from sliding or sliding within the package. This reduces the chance of damage during shipping and handling.

- Improve branding: Flocking can be used to create patterns or designs on packaging, which can help reinforce the brand and make the product more memorable. This works especially well for luxury or high-end products.

- Eco-Friendly: Flocking can be made from recycled materials and is biodegradable, making it an environmentally-friendly packaging option. This can appeal to environmentally conscious consumers and companies. Reflective properties: Foil stamping creates a reflective surface that enhances the brightness and clarity of printed or embossed text or designs.

Summarize

With the continuous development of science and technology, printing technology is also constantly improving. I hope you can find your printing inspiration from this article. If you have any unsolvable problems in packaging box printing, you are welcome to ask us questions, JERL aims to Find the most suitable packaging method for each product.

JERL has been working hard on the road of custom packaging. Next time when you feel the need to impress someone with your brand, think of JERL Packaging!